What is grading of aggregate?

The particle size distribution of aggregate, as determined by sieve by sieve analysis, is termed as the grading of aggregate. The gradation of aggregate plays a vital role in governing properties like workability and finishing. If all the particles of an aggregate are of uniform size, then compacted mass will have maximum voids, whereas particles of different sizes lead to dense mass. The particle size distribution of aggregate should be in such a manner that voids of larger particles are to be filled up with smaller particles.Note

- Proper grading of aggregates results in dense concrete and requires less quantity of fine aggregate and cement paste.

- Grading of aggregate affects the workability which, in turn, controls the water and cement requirements, segregation and plays an important role in placing and finishing operations of concrete.

Types of grading of aggregate

It is also mainly dependent upon the different sizes of particles available in the aggregate, the grading may be of the following four types are the given below.

1. Well graded aggregates

The aggregate is said to be well graded if the voids created by large-sized particles are filled almost by smaller size particles hence leaving minimum voids to be filled by cement paste. Well, graded aggregate contains all sizes of particles, thus leading to a compact and dense mass of concrete mix. This type of grading is considered the best because all sizes of particles are available, which leads to a lesser quantity of cement requirements.

2. Gap graded aggregates

2. Gap graded aggregates

When the particles of certain sizes are missing in aggregate then the grading is termed as gap graded. Most of the crushers in India are single size crushers thus creating single size aggregates. The gap-graded aggregate does not affect compressive or tensile strengths

3. Poorly graded aggregates

3. Poorly graded aggregates

The grading in which the proportions of certain intermediate particles are deficient or in excess is termed as poorly graded aggregate.

4. Continuously graded aggregates

4. Continuously graded aggregates

Aggregate is said to be continuously graded when it contains all particle size groups i.e., from the maximum particle size to the minimum size. Such grading is termed as coarser or finer depending upon the higher proportions of coarser or finer particles they contain in reference to specified grading with which they are being compared.

Factor affecting the effects of grading of aggregate

The grading of aggregate has the following effects on the properties of fresh and hardened concrete. It is mainly four types are the following given below.1. Density of aggregates

The well-graded aggregate has a lesser number of voids as compared to particles of the same size. Thus proper grading of aggregate produces dense concrete and requires less quantity of cement to fill the voids. Therefore, the concrete produced is economical.

2. Segregation of aggregates

2. Segregation of aggregates

Segregation is an undesirable property in fresh concrete. Coarser grading tends to segregate if the required proportion of finer material is not available to maintain cohesiveness. Therefore, with the help of grading the deficient particles can be maintained.

3. Bleeding of aggregates

3. Bleeding of aggregates

Bleeding is an undesirable property in fresh concrete. Lack of finer grading leads to bleeding. Bleeding is more in case of coarser grading of aggregate.

4. Strength of aggregates

4. Strength of aggregates

Grading of aggregate has no direct effect on strength but indirectly influences the strength parameters. For concrete having a low water-cement ratio, coarser grading is required because it provides less specific surface area. Whereas, for high water-cement ration finer grading is desirable.

The upper and lower grading limits of different types of aggregates are expressed in terms of percentage of aggregate passing through a set of Indian Standard sieves. Grading limits for coarse aggregates, fine aggregates, and all in-aggregates are described below.

1. Grading limits for coarse aggregate

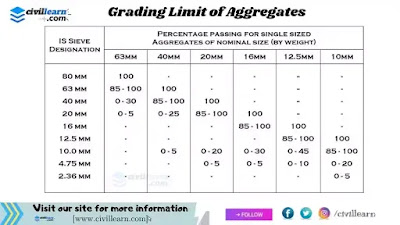

Grading Limits of aggregate

There is no universal ideal grading curve. Various grading of aggregates can be used to get the satisfactory performance of concrete. Sometimes aggregates available at the site may not be of specified or desirable grading. In such cases, two or more aggregates from different sources may be combined to obtain the desired grading. However, IS - 383 - 1970 has specified certain limits within which the grading must lie to produce satisfactory concrete, subject to the fulfillment of certain desirable properties of aggregates like the type of aggregate (i.e., coarse or fine), shape (round or angular), surface texture (rough, glassy or smooth), etc.The upper and lower grading limits of different types of aggregates are expressed in terms of percentage of aggregate passing through a set of Indian Standard sieves. Grading limits for coarse aggregates, fine aggregates, and all in-aggregates are described below.

1. Grading limits for coarse aggregate

The grading of coarse aggregate may vary through wide limits as compared to sand because it does not affect the properties (like uniformity, workability, and finishing) of concrete mix. The grading of coarse aggregates both for the single size and well-graded should be as per the limits specified in Table

2. Grading limits for fine aggregates

2. Grading limits for fine aggregates

It is difficult to control the grading of fine aggregate. As per IS 383_1070, the sands are generally divided into four different zones according to the percentage passing the IS - 600 microns sieve.

3. Grading limits for all-in-aggregate

3. Grading limits for all-in-aggregate

In the case of all-in-aggregate, the necessary adjustments may be made in the grading by adding single size aggregate without separating into fine and coarse aggregates. The grading of all-in-aggregates should be as per the values specified. Grading Limits For All-in-aggregates

Note

- If the grading of all-in-aggregate, when determined, lies in zone A then the aggregate is classified as good grading.

- If the grading of all-in-aggregate lies in zone B, then it is classified as tolerable grading.

For a given aggregate, the grading can be assessed by conducting sieve analysis. The percentage of aggregate passing through IS sieve is calculated. These values are plotted on the corresponding chart and interpreted as under

- If the actual grading curve lies below the specified grading, then the aggregate is considered to be finer, and hence more water will be required. The quantity of cement required for a constant w/c ratio will be more for such gradings. Such type of grading is uneconomical.

- If the actual grading curve lies above the specified grading then the aggregate is considered to be coarser. Such type of aggregate in a concrete mix is at a high risk of segregation.

- When the actual grading curve is flatter than the specified grading curve, then the aggregate may be deficient in the middle size particles.

- When the actual grading curve is steeper than the specified grading curves, then the aggregate may contain an excess of middle size particles.

For more information watch this video

![[3] Main method of estimation | Center line method and Long Wall-short Wall method](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEi-tUtY1W3S747Ws8mkCIvT9rCeji2iB5dIgISp1Y3SnuuLT3kcHKc6pm-eTghLLCoPSATf4L_dBVMvDCcstWv99RZc6ddp4yVoWT2mthaDW-1569tju756sMH3c3gDJZ_6iMkGcbd7c5U/w680/estimation+of+building.jpg)

0 Comments

Please do not enter any spam link in the comment box.